Why We Should Care About Concrete

City of Greenville, North Carolina, via Wikimedia Commons

Concrete underpins modern life—but its production carries a staggering environmental cost, with global demand only set to grow. As new solutions like LC3 and bio-cement emerge, they offer promising pathways to cut emissions and rethink how we build, leading the way for other traditional industries.

Concrete is humanity’s favorite building material. It is also the most polluting. Concrete is strong, versatile and indispensable to modern civilization, but its carbon cost is extreme. If the industry was a separate country, it would be the world’s third worst CO₂ emitter, producing more than the total for India. And demand is expected to increase, especially in the developing world. India is adding new manufacturing capacity for around 35 million tons of cement (concrete’s main ingredient) per year—equal to the total already built in Germany.

Concrete has been used as a building material for thousands of years. Many properties make it the most preferred building material. It’s fireproof, waterproof, surprisingly adaptable for what is essentially rock, as well as strong and cheap. Concrete also offers:

- Safety—Concrete does not rust, rot or burn, making it the primary choice for structures where safety is essential.

- Resilience—When properly reinforced, concrete can withstand fires, earthquakes, hurricanes, floods, and even warfare.

- Long life—Concrete structures are long-lasting. Some Roman concrete structures are still in use thousands of years later. Concrete structures require fewer repairs that would produce additional emissions.

The Weight of the World

Carbon dioxide is an unavoidable byproduct of cement production and accounts for almost all that comes from making concrete. Each year the world produces some four billion tons of cement. For every ton of cement made, almost a ton of CO2 is released, totaling roughly eight percent of global emissions. Sixty percent of the emissions result from the heated limestone and forty percent is from burning the fuels needed to heat it. Until recently it seemed there was little that could be done about this, but now it’s in the interest of the cement industry itself to change. The world’s largest cement producers—Cemex, Holcim Limited, Heidelberg Materials and others—have all set net-zero targets for 2050 or thereabouts.

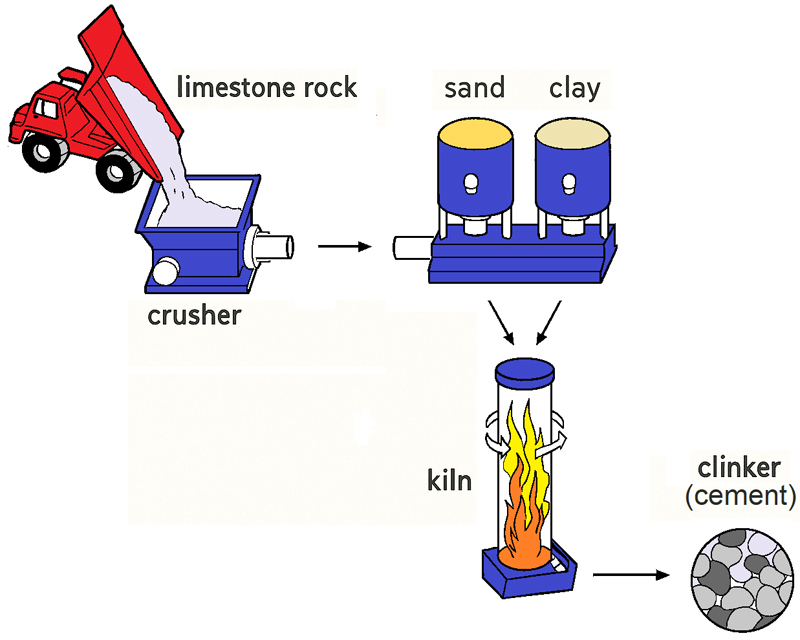

The Romans made cement by heating limestone, then adding sand to make mortar and stones to make concrete. Today concrete is made using Portland Cement, named in 1824 after a stone quarry in England. It is made by heating limestone with other materials, including gypsum, to 1450°C (about 2650°F). This process drives carbon dioxide from the limestone to leave calcium oxide (“lime”). Lime combines with sand and clay other materials in the mix to form cementing compounds. These are ground into a powder to make Ordinary Portland Cement(OPC). There is another crucial step to make OPC bind rock and sand into concrete—when water is added, the OPC becomes a gel-like substance that hardens into a dense network and binds the aggregate.

A Hard Problem

Dozens of startups, according to the venture capital firm 2150, are attempting to decarbonize concrete. Today only a few decarbonization schemes are economical. Consumers of concrete are looking to reduce the amount used in new designs by replacing concrete with materials such as wood where possible. Smarter designs using advanced software can reduce the amount of concrete used and extend the lifespan of structures. But while these approaches are important, they do not come close to offsetting the rapidly growing need for more cement and eliminating the CO2 released in making it.

Some partial solutions are already on hand. While a modern cement plant, such as the Pennusco plant in Florida, can cost upwards of $100M to build, these modern factories use high-efficiency kilns and automated processes to reduce costs. Electric furnaces using sustainable power eliminate emissions from fossil fuels. The heat from the kilns can be used to pre-heat the limestone. These modifications have been shown to cut energy use by 30% compared to older plants, reducing the energy contribution to emissions. But the greatest need to lower carbon emissions is to change cement itself. Reducing OPC content in the mix is the best way to make concrete greener.

Gray Matter

Manufacturers are using fly ash to reduce their reliance on OPC. Fly ash, a powdery by-product of coal combustion, behaves like cement. The carbon in making it has already been released into the atmosphere, so adding fly ash reduces cement emissions. Fly ash makes concrete stronger and makes it easier to pump at construction sites. Slag waste left from making steel in blast furnaces has similar benefits. But while plentiful today, these materials are not long-term solutions. Burning coal for energy and using blast furnaces to make steel are being phased out.

The search is on for more abundant and inexpensive materials. There are no practical substitutes yet that can replace most of the OPC, but Limestone Calcined Clay Cement (LC3), is one of the most promising. Adding clay to cement is not new but the innovative LC3 process uses cheap, low-grade clays that previously would have degraded the concrete mix. LC3 is also fired at lower temperatures. If LC3 can be produced at scale, it could reduce CO2 emissions where it is employed by about 40%. It’s expected to find acceptance fastest in the Global South, where concrete demand is soaring and these clays are abundant.

Limestone itself is the most commonly used additive today. Adding finely ground limestone to the mix produces Portland-Limestone Cement (PLC). It typically emits about 10% less CO2 than OPC and is on track to become the new standard for construction. Many other possibilities are being pursued. Brimstone, a startup in Oakland CA, is developing cement from abundant carbon-free silicate rocks. Concrete recycled from demolitions is another possible additive, although this resource, like slag and fly ash, is limited.

Concrete Plans

A combination of these measures might someday halve cement’s carbon footprint. More is needed, but until novel materials prove safe and durable, the cement industry is understandably cautious. If a bridge or dam built using a new cement were to collapse, many lives could be lost, and the financial fallout would be ruinous. Such an event might discredit not only a specific new material but the entire effort to replace cement. Another route to reach net-zero by 2050 is needed. That route is carbon capture and storage (CCS).

CCS refers to several processes that capture CO₂ at a point source before it is released to the atmosphere. CCS is costly. It requires additional complex chemical processes, pipelines and storage facilities. On the plus side, these can be bolted on to the infrastructure already in place. What to do with the captured CO₂ is difficult. Currently, most is injected into depleted wells to extract more oil. While the captured carbon dioxide is permanently stored, this is far from ideal. CarbonCure, a Canadian firm, injects captured carbon into wet concrete, improving its strength and reducing the amounted needed for a structure, but this sequesters only a fraction of the emissions.

Heidelberg Materials has begun sequestering CO₂ from its Brevik plant in the world’s first large CCS system for cement. With sizable investments from the Norwegian government and major oil companies, the factory will soon produce cement with net-zero emissions. The captured carbon dioxide is being injected into bedrock more than a mile below the North Sea and is not being used to extract oil. Heidelberg is constructing an even larger facility in Sweden with plans to be carbon-negative by 2030, sequestering not only the cement’s emissions but also drawing CO₂ from the air.

Growing the Future

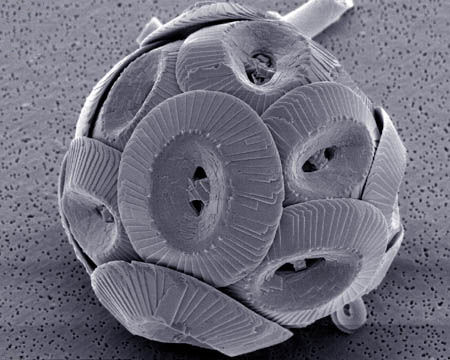

There is an entirely different approach to improving concrete—one so revolutionary it could literally change the planet. Rather than digging limestone from quarries, it can be grown in much the same way that marine life makes seashells. What is more, limestone produced by this “biomineralization” does not need to burn away carbon to make cement. Rather, growing limestone by microorganisms at near room temperature allows the CaCO₃ to become the cementing material itself. Instead of chemically combining with water to bind the aggregate like OPC, it fills the spaces in the material to bind it mechanically. It becomes, essentially, artificial limestone.

Microscopic plates of limestone formed by algae comprise most of the famous White Cliffs of Dover. Mimicking this biology may enable cement to be grown free of carbon emissions (images: Richard Lampitt & Jeremy Young, and Immanuel Giel, Wikimedia Commons)

To grow the limestone, organisms such as bacteria, algae, or fungi are used to draw carbon from the atmosphere or seawater and lock it away. In principle the process might even sequester the carbon emitted by burning fossil fuels, such as in coal plants. The commercial challenges are much the same as for other alternatives to OPC. Can bio-cement be produced economically in large quantities in a timely fashion? Is the material safe, strong, durable, and easy to work with? One type of bio-cement is being produced commercially by start-ups including Biomason in Denmark and North Carolina, and Prometheus Materials in Colorado.

This commercial bio-cement is somewhat different—a form of conventional OPC. The carbon in the limestone is still burned away to produce lime, but while this does not sequester the carbon, it only releases carbon that was drawn from the air when making the limestone. If combined with sustainable energy for the heat to produce lime, the entire process can be carbon neutral. Concrete using this cement is used for low- to moderate-strength applications such as flooring. It does have some production advantages. It can be grown anywhere, near cities or wherever it is needed—the manufacturing equipment can even be portable. It uses comparatively little energy and is non-polluting.

Persistent Pressure

Tackling collective challenges requires collective action. No individual can solve them alone. Voters must support candidates who understand that climate change is complex—a multidimensional threat, rather than a possible problem that should be left to the future. Students must continue to refuse to accept that risk. By adopting policies that favor low-carbon concrete, governments can help manufacturers offset the higher costs of early adoption and achieve the economies of scale that long ago made conventional concrete cheap.

Green concrete may not capture the imagination like solar panels or electric cars, but it is no less crucial to the planet’s low-carbon future. Meeting the world’s climate targets will require greening concrete and the cement that binds it together. Encouragingly, innovation and investment are already beginning to solve what once seemed an unsolvable problem—proof that human ingenuity, when properly motivated, can lighten the gloom that so often clings to climate change.

External Stories and Videos

UCLA project explores carbon capture through ocean water

CBS LA

UCLA's SeaChange project uses ocean water and electricity to trap carbon dioxide from the atmosphere into solid material, which can produce hydrogen "green energy." Dante Simonetti, associate director of the UCLA Institute of Carbon Management, joins KCAL News Mornings to discuss the technology.